LDPE (Low-Density Polyethylene) air ring is a crucial component of a film blowing machine used in the production of LDPE films. It is responsible for creating a high-velocity air stream that cools and solidifies the molten LDPE resin as it emerges from the die.

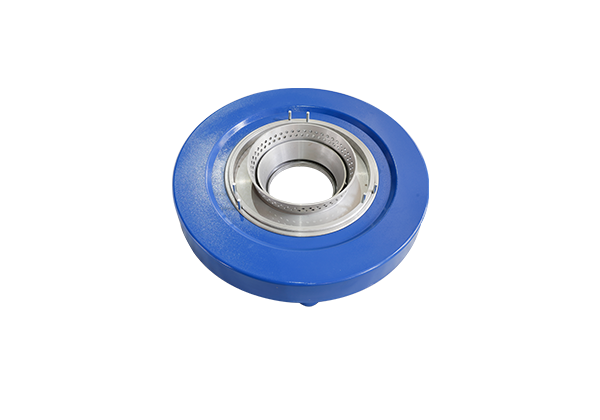

The LDPE air ring typically consists of a circular housing with multiple air nozzles or slots positioned around its circumference. These nozzles direct a stream of cool air onto the hot extruded LDPE film, promoting rapid cooling and solidification.

The primary function of the LDPE air ring is to control the cooling process and maintain consistent film quality. It helps in achieving uniform film thickness, enhancing transparency, and reducing the risk of defects such as bubbles or unevenness. By controlling the cooling rate, the air ring allows for the desired physical properties of the LDPE film to be achieved, such as flexibility, toughness, and clarity.

The design and configuration of the LDPE air ring can vary depending on the specific requirements of the film being produced and the machine manufacturer. The air ring is typically adjustable, allowing operators to fine-tune the cooling process based on the production parameters and desired film characteristics.

In summary, the LDPE air ring in a film blowing machine plays a vital role in the production of LDPE films. It controls the cooling and solidification of the hot extruded LDPE resin, ensuring consistent film quality in terms of thickness, transparency, and physical properties.