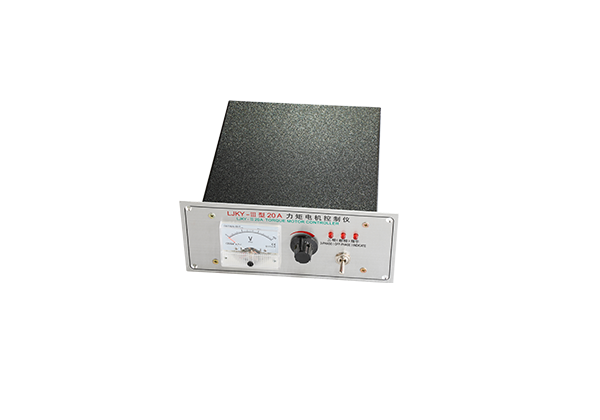

Torque motor Speed controller

The speed controller board of the torque motor on a film blowing machine's winding unit is responsible for adjusting and controlling the rotational speed of the winding motor. This control board plays a crucial role in ensuring the proper winding and tension control of the film being produced.

The torque motor in the winding unit is designed to provide a specific amount of torque or rotational force to wind the film onto the reel. The speed control board regulates and adjusts the speed of the torque motor to maintain the desired tension and winding quality of the film.

By adjusting the speed, the control board ensures that the film is wound evenly and without any wrinkles or distortions. It also helps in controlling the tension during the winding process, preventing overstretching or loose winding, which can affect the quality and functionality of the film. The control board typically allows operators to set the desired winding speed and provides feedback through sensors or feedback mechanisms to maintain the desired speed and tension. This enables precise control over the film winding process, ensuring consistent quality and efficient production.

In summary, the speed control board of the torque motor in the film blowing machine's winding unit is responsible for adjusting and controlling the rotational speed of the winding motor. It ensures precise control of winding speed and tension, resulting in high-quality, evenly wound film products.