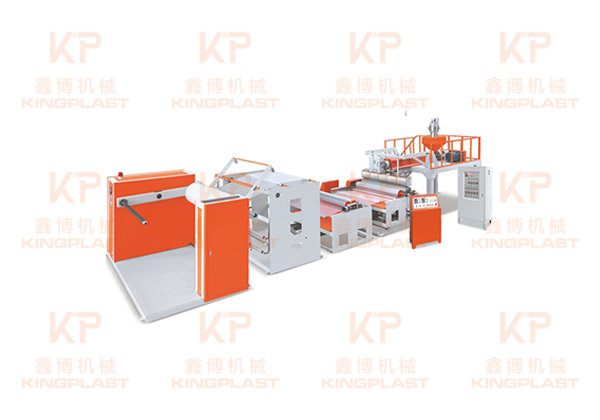

2 Layer PE Air Bubble Film Machine ( Double Screws )

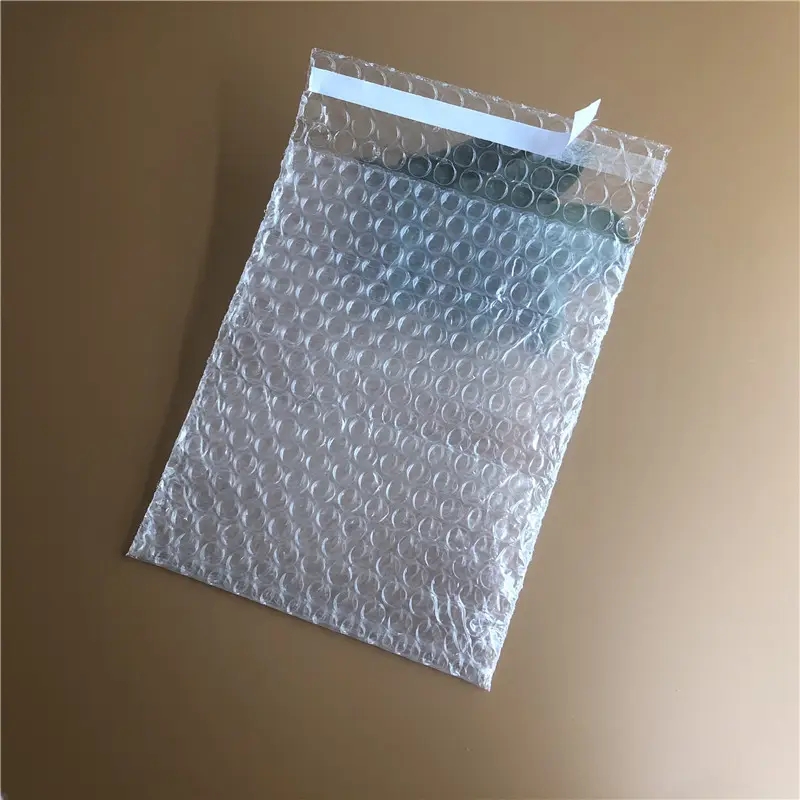

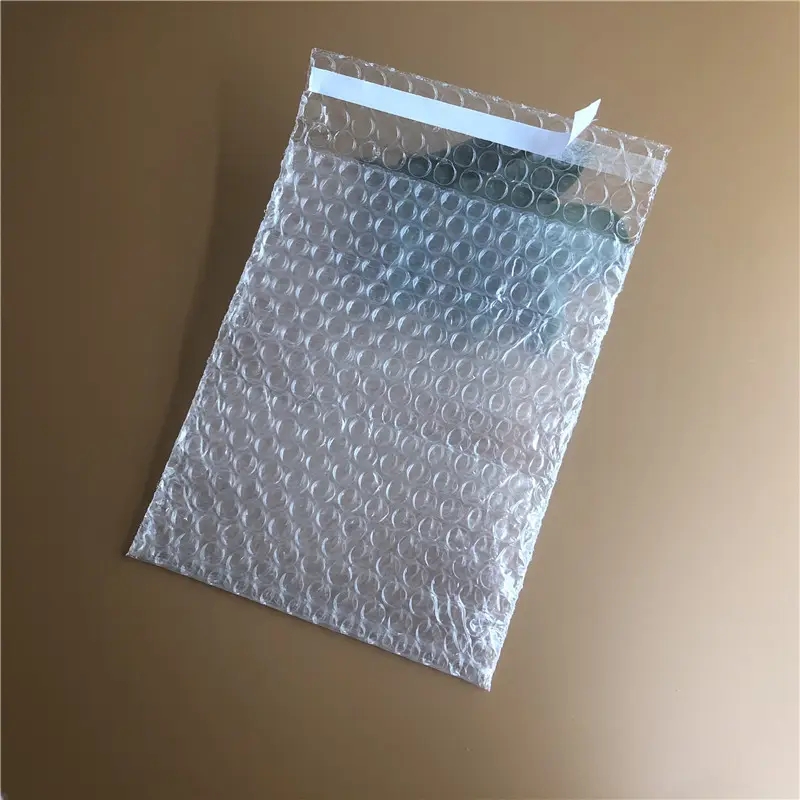

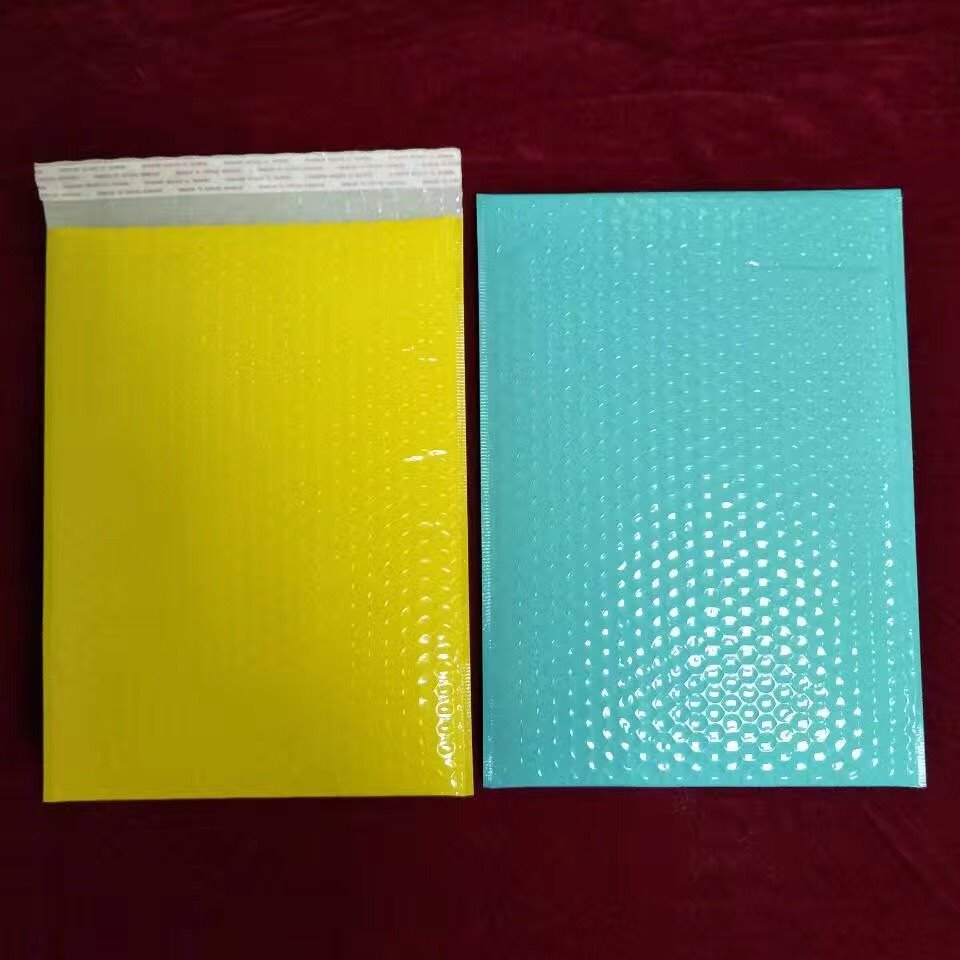

Application : express bags , shockproof package film ,envelope bags

Descriptions:

This air bubble machine adopts the disposable shaping craft.It is our factory that draws domestic and international advanced technology extensively, through a large number of production practices in having ordinary equipment originally, develop, design, can produced polyethylene air bubble (cushion) film in successions. Designs science, practical and rational structure of the machine.

It not only has good cushioning effect, shock resistance and heat resistance, but also has such advantages as good corrosion resistance and transparency , etc.

So it has been widely used for packing, household wares, post parcel, bicycle , polyurethane furniture, etc.

Feature:

1. Main parts: 2 Extruders , Control Panel, Bubble forming section, Automatic Winder,Rewinder.

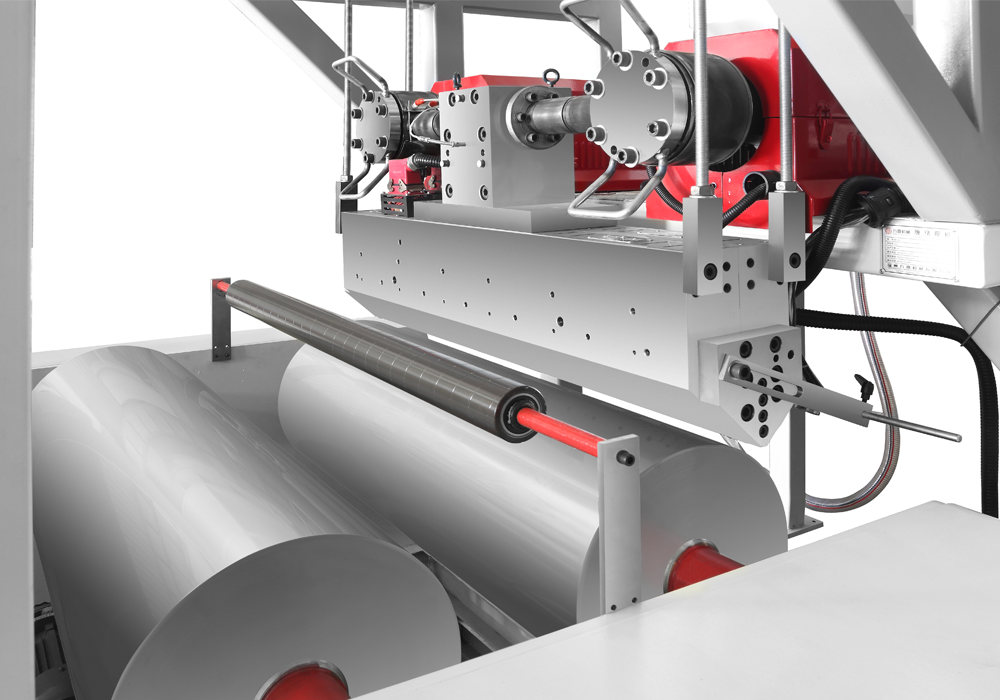

2. Produces two layers air bubble film(Bubble Layer + PE Layer. ).

- The laminated layer can be aluminized foil, MPET foil, kraft paper, EPE foam, BOPP film etc.;

- Each layer is under individually control, can have different thickness & material formulation and color;

- Film width from 1,000mm to 3,000mm;Or Customized size.

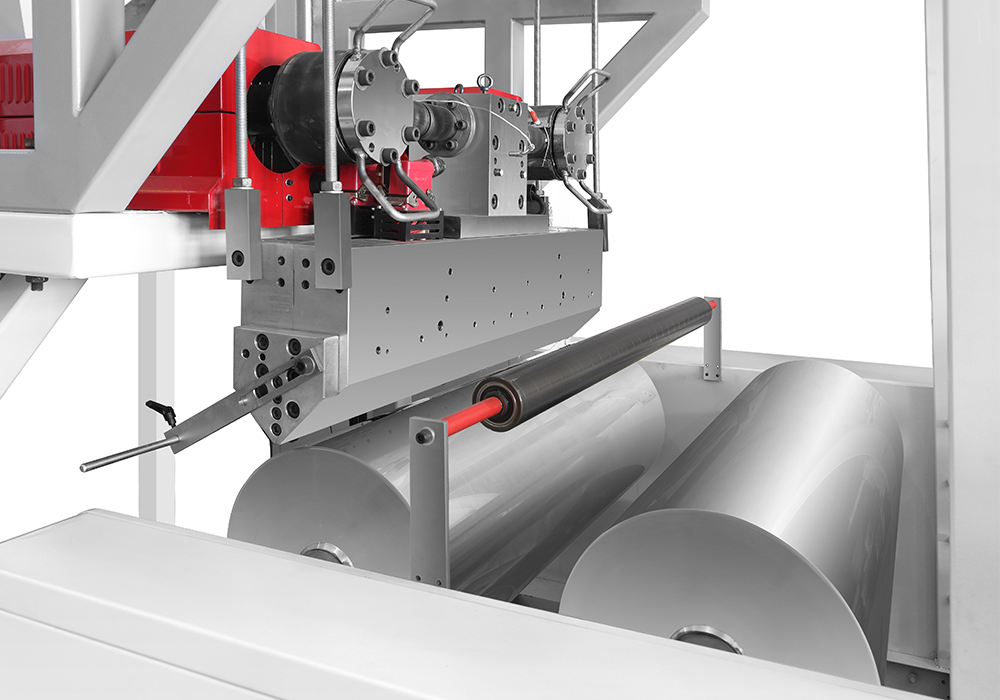

- Screw L/D ratio is 1:32, it adopts special mixing function and high plasticizing capacity design, with good plasticization, good mixing effect and high output;

- The bubble forming cylinder adopts special internal circulation chilled water design to ensure perfect bubble forming effect under high speed operation.

8. Machine include two extruder,two hydraulic net changer,two auto loader,edge trim recycle,auto cutting and auto winding system.

Optional equipment:

1. Chiller

2. Automatic Vacuum Feeder

3. Auto Changing Sieve

4. Blender

5. Scrap Reverse

6. Grinder

7. Auto Rewinder

8. In-line perforated unit

|

Model |

KPAB100-2S |

KPAB180-2S |

KPAB200-2S |

KPAB250-2S |

KPAB300-2S |

|

Max width mm |

1000 |

1800 |

2000 |

2500 |

3000 |

|

Screw diameter mm |

65 |

85 |

90 |

110 |

120 |

|

Main motor power kw |

18.5 |

30 |

37 |

45 |

55 |

|

Capacity Kg/hr |

5-70 |

80-110 |

95-120 |

105-165 |

120-180 |

|

Line speed M/hr |

8800-2000 |

8800-2000 |

8800-2000 |

800-1500 |

800-1500 |

|

Heating power kw |

43 |

50 |

55 |

72 |

80 |

|

Running power kw |

21 |

36 |

40 |

45 |

55 |

|

Total power kw |

71 |

106 |

119 |

145 |

170 |

|

Raw material |

LDPE/LLDPE/Recycle material |

||||

|

Machine Weight kg |

5000 |

7600 |

7800 |

8900 |

9200 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|