ABA Film Blowing Machine

Descriptions:

Suitable material : HDPE, LDPE ,LLDPE

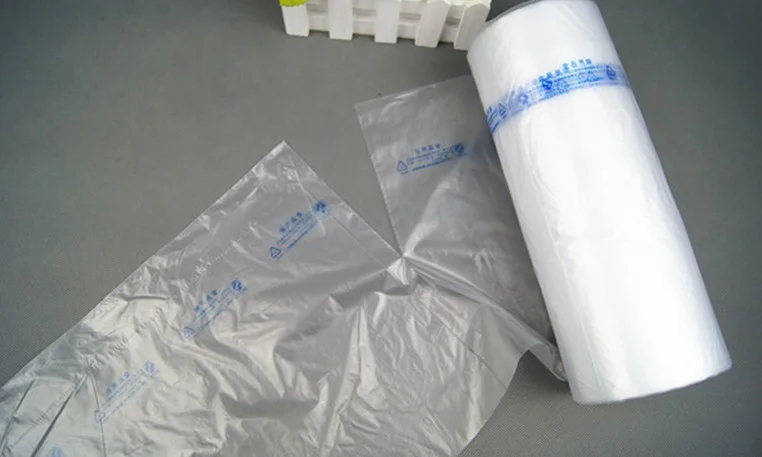

ABA film blowing machine is used to produce t shirt bag/vest bag ,garbage bag on roll ,flat bag , supermarket bag, shopping bag , express bag,industrial packaging, agricultural films .

Feature:

ABA film blowing machine ,provides a good solution for general packaging and produces quality film of LDPE,HDPE,LLDPE. Such as t shirt bag/vest bag , bag on roll garbage bag ,flat bag, supermarket bag, shopping bag , express bag., industrial packaging, agricultural films .Film width can be customized according to customer requirements, from 200mm to 1500mm. High precision die head and cooling air ring provide good film thickness control and resistance.

This ABA PE blown film machine is specializing in producing high performance ABA co-extrusion PE film, adopts A, B double hosts (one for the inner and outer layers (A layer) and one for the middle layer (B Layer) and co-extruison A+B+A blown film die head, in the ABA PE blown film machine, using one host for the inner & outer layers and other host for the inner layer, two kind material are heated and formed into three layer film, with the ABA multi-layer co-extrusion, it could significantly improve the physical strength of the PE film. Compared with the three layers co-extrusion PE blown film machine, this ABA PE blown film machine reduces one host, produces the three-layer co-extrusion film, at the same time, achieves the purpose of reducing costs, saving energy and reducing consumption etc. In the middle layer of the ABA PE blown film machine, recycled materials or calcium carbonate material or other cheap materials are applicable added, and even adding 50% calcium carbonate (the strength, weldability and printability of produced PE film is not affected at all), and the middle layer is cooled faster with calcium carbonate or low-pressure polyethylene to produce higher yields.

Optional Equipment:

1. Auto-loader

2. Dryer

3. Corona treater

4. Rotary die head

5. Double winder

6. AirCooling device

7. High speed screen changer

8. High quality electricity parts

9. Air Shaft

|

|

|

|

|

|

|

|

|

|

|