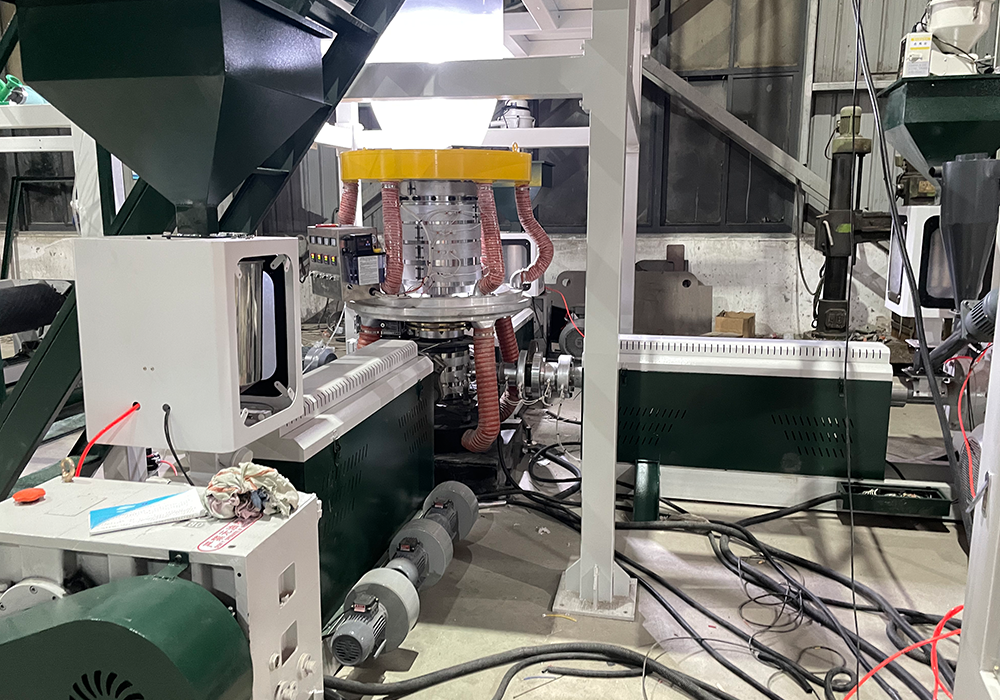

ABC - 3 Layer Co-extrusion Film Blowing Machine

Descriptions:

Suitable material :HDPE , LDPE, LLDPE

The ABC 3 layer co extrusion film blowing machine is used to produce symmetrical film, including liquid packaging film, shrink/stretch film, electrostatic protection film, the waterproof film in ponds, heavy packaging film, Construction film , Construction sheeting ,Food packaging etc.

Feature:

ABC type 3 Layer co extrusion film blowing machine it can be used for the production of a wide range of general packaging films, and can be used to produce symmetrical film, including liquid packaging film, shrink/stretch film, electrostatic protection film, the waterproof film in ponds, heavy packaging film, etc. Film width can be customized according to customer requirements, from 800mm to 2500mm. High precision die head and cooling air ring provide good film thickness control and resistance.

It operates based on the principle of multiple extruders simultaneously melting and extruding different types of plastic resins, which are then combined to form a three-layered film.

1. Multiple extruders: This machine consists of at least three extruders, each responsible for melting and extruding a different type of plastic resin. The extruded resins are then combined to form three layers.

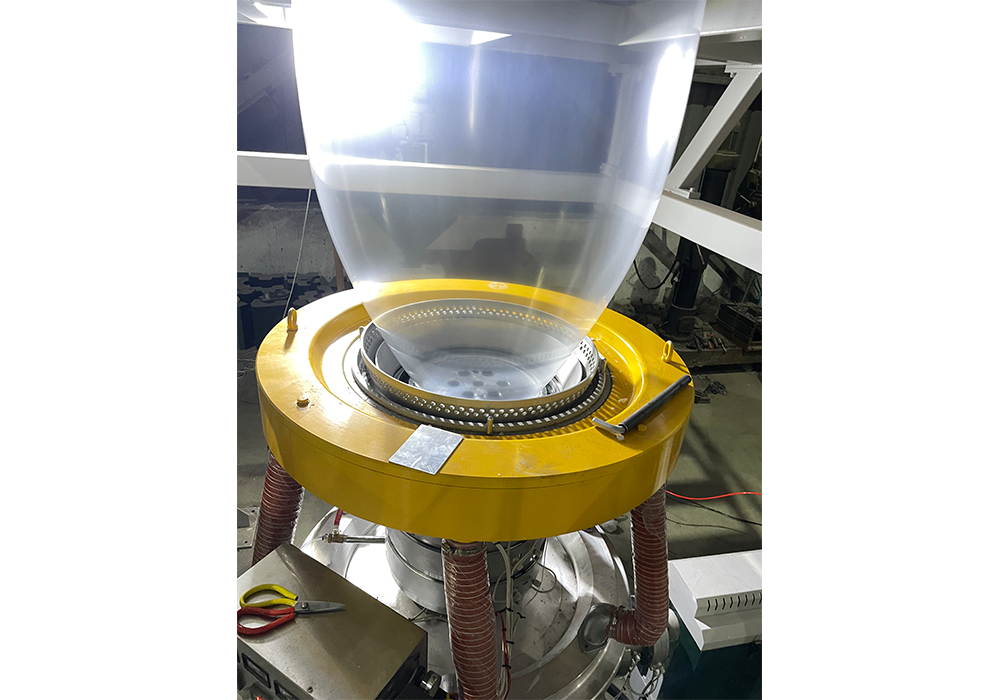

2. Die head: The die head is an important component that controls the flow and distribution of the molten resins. It allows the three layers to be evenly distributed and ensures the film thickness remains consistent throughout.

3. Air cooling ring: After the molten resins pass through the die head, they are inflated using compressed air. The air cooling ring helps to cool down the film, increasing its solidification rate and enhancing its properties.

4. Take-up unit: The take-up unit is responsible for winding the film onto a reel in a controlled manner. It ensures proper tension and alignment during the winding process, resulting in a neat and uniform roll of film.

5. Control system: The three-layer co-extrusion blown film machine is equipped with a control system that allows operators to adjust various parameters such as temperature, speed, and thickness. This system ensures precise control over the production process and enables the production of films with consistent quality.

Optional Equipment:

1. Autoloader

2. Corona treater

3. Air cooling device

4. Auto winder changing system

5.Wash film crusher

6.Fast screen changer

7.Sealing knife

8. Haul-off rotary

9. Internal Bubble cooling(IBC)

10. Automatic edge position correction

|

Model |

KP-SJ3L1200 |

KP-SJ3L1500 |

KP-SJ3L 2000 |

|

Suitable material |

HDPE LDPE LLDPE |

||

|

Film width(mm) |

800-1200 |

1000-1500 |

1200-2000 |

|

Single side Film thickness(mm) |

0.028-0.20 |

0.028-0.20 |

0.03-0.20 |

|

Max.Extrusion output(kg/hr) |

120 |

150 |

200 |

|

Extruder |

|||

|

Screw diameter(mm) |

Aφ50Bφ50 Cφ50 |

Aφ55Bφ60 Cφ55 |

Aφ60Bφ65Cφ60 |

|

Screw L/D length |

30:1 |

||

|

Screw material |

Bimetallic |

||

|

Cylinder material |

SACM-645/38CRMOALA |

||

|

Cylinder cooling |

370wx2 *3unit |

370wx3* 3unit |

3700wx3*3unit |

|

Driving motor (kw) |

18.5 * 3 |

A22+B30+C22 |

A30+B37+C30 |

|

Temperature control |

3X3 |

3 X3 |

3X3 |

|

Type of die |

|||

|

Die size |

280 |

400 |

500 |

|

Temperature control |

4 |

||

|

Air ring |

1 |

||

|

Air blower(kw) |

7.5kw |

11kw |

15kw |

|

Center steady stick |

1 |

||

|

Take-up unit |

|||

|

Roller width(mm) |

ф165×1300 |

ф190X1600 |

ф190x2100 |

|

Take-up speed(m/min) |

5-60 |

5-50 |

5-50 |

|

Take-up motor(kw) |

1.5 |

2.2 |

2.2 |

|

Winding unit |

|||

|

Type |

Surface friction type |

||

|

Winding motor(kw) |

1.5kw |

2.2kw |

2.2kw |

|

Winding speed(m/min) |

5-50 |

5-50 |

5-50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|