Laboratory Film Blowing Machine

.png?x-oss-process=image/resize,w_100/quality,q_100)

Suitable material : HDPE ,LDPE ,LLDPE ,PLA , PBAT, PAV,EVA

Specification:

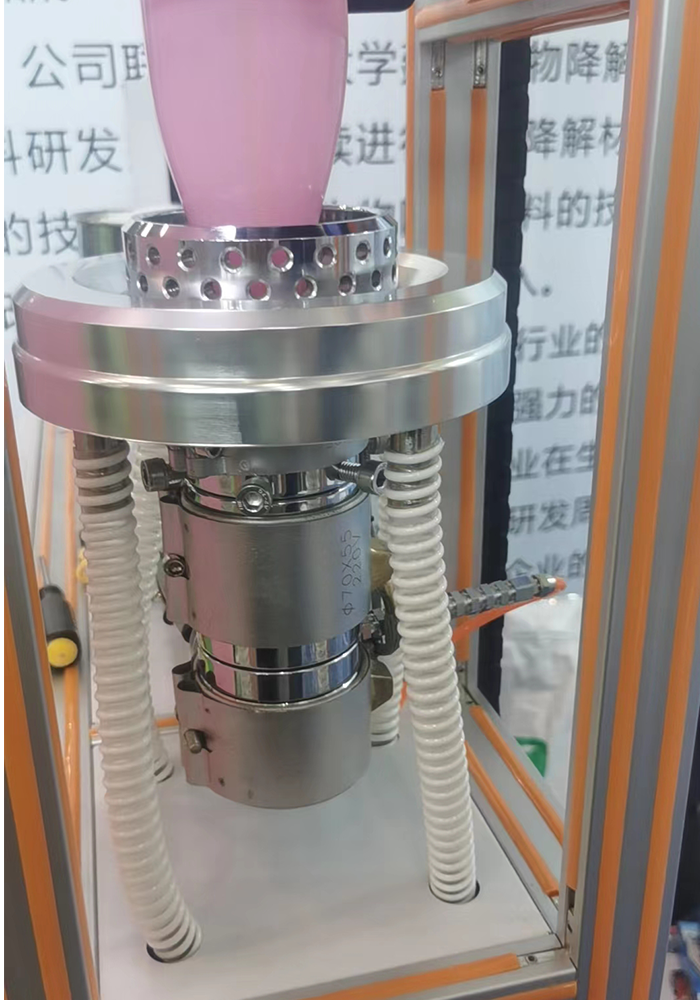

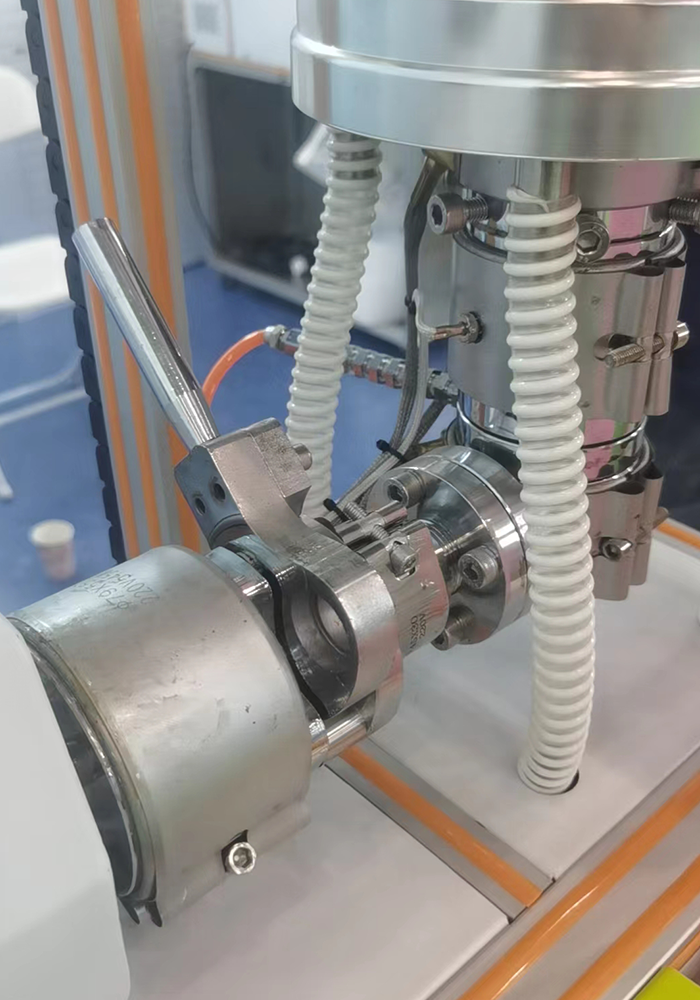

The LB-16 Model Laboratory film blowing machine ,also called lab extruder, laboratory extrusion line – Developed, engineered, assembled tested by Kingplast Machinery

New grains and polyethylene formulas are entering the market due to the demand for more environmental friendly solutions for end-products. Bio-plastics and Bio-degradable products are increasingly becoming more demanded. This calls for a need to test material before launching the material into the master batches. Therefore, we would like to show here our laboratory extrusion line

LB-16 models are ideal for new material formula development, film blowing property test, master batch colour dispersion test, optimization of blown film extrusion process parameters, or simply for production of monolayer tubular blown film. The lab extruder can process biodegradable and compostable bioplastics, recycled material, PE, LDPE, LLDPE, PP, masterbatch, plastic additives, as well as functional masterbatch. The Lab extruders are useful machines to analyse the film blowing properties of a given material which allows you to save money by testing various type of materials formulation before going into production and obtain better quality films.

|

Model |

LB-16 |

|

|

Suitable material |

PE ,PBAT ,PAV,EVA |

|

|

Screw Diameter |

Φ16 |

Hangzhou zhoushan |

|

RV40 gear box |

RV40 |

Jiangsu,National standard |

|

Screw L/D Ratio |

30:1 |

Hangzhou zhoushan |

|

Screw material |

Bimetallic |

Hangzhou zhoushan |

|

Screw(r/min) |

110 |

|

|

Screen changer |

Manual double station |

|

|

Heaters material |

Steel stainless |

Shantou |

|

Die head |

Φ70 |

Special design for biodegradable material |

|

Max folding width |

150mm |

|

|

Roller width |

160mm |

|

|

Film thickness |

0.02-0.1mm |

|

|

Linear speed |

0-10m/min |

|

|

Capacity |

1-2kg/h |

|

|

Die gap |

0.6 |

|

|

Air ring |

180mm |

Hangzhou |

|

Operation temperature |

250 ° |

|

|

Temperature control accuracy |

±1° |

|

|

Main motor |

600 servo motor 1.98N |

|

|

24VDC Air blower |

100W |

|

|

Working Voltage and Current |

220V7A/50hz |

|

|

Electricity Box |

|

|

|

Main Servo power |

600W1.9N |

|

|

take up motor |

100W |

|

|

Temperature control |

5zone |

Shanghai AISET |

|

Solid relay |

5zone |

Omron |

|

relay |

--- |

CHINT |

|

Air switch |

--- |

CHINT |

|

Button switch |

--- |

CHINT |

|

Control Panel |

4.3 inch touch screen |

|

|

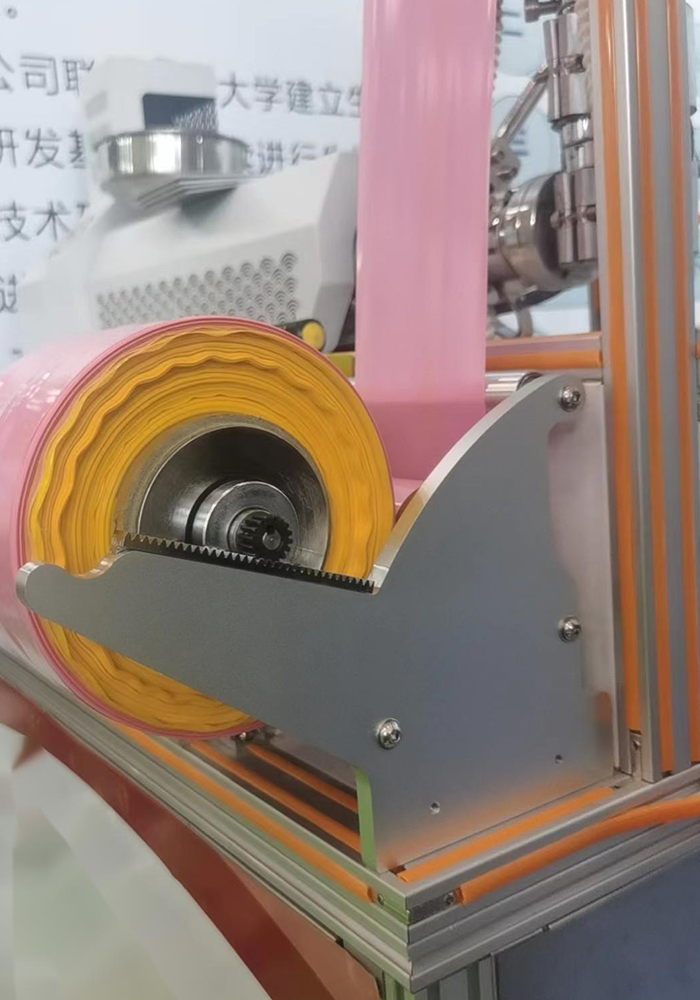

Take up unit |

|

|

|

Reducer |

100W |

|

|

Rubber Roller width |

150mm |

|

|

Rubber Roller diameter |

Φ40 |

|

|

Pressure roller width |

150mm |

|

|

Winding unit |

|

|

|

Single winder |

|

|

|

winding type |

Back to back |

|

|

winder frame thickness |

10Mm |

|

|

Rubber roller diameter |

Φ50 |

|

|

Machine dimension |

|

|

|

L*W*H |

800×500×1000 |

|

|

L*W*H (after folding ) |

800×500×700 |

|

|

Machine weight |

67kg |

|

|

|

|

|

|

|

|

.png?x-oss-process=image/resize)

.png)