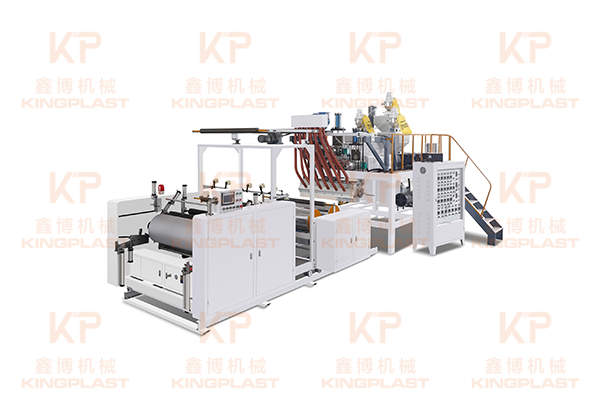

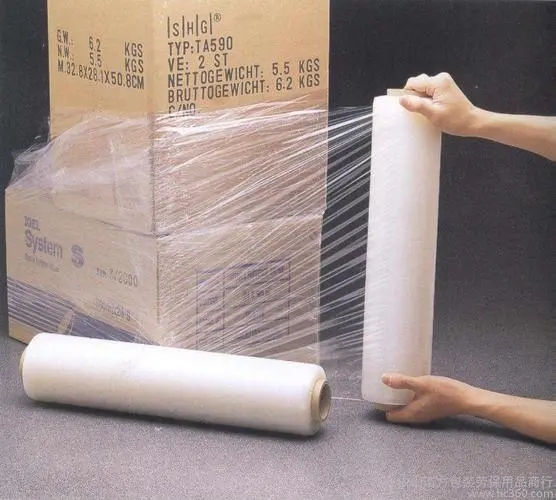

Application : This line is designed for producing single/double-side self-adhesive three-layer stretch film by extruder with LLDPE and several kinds of resins.

Structure of film layers : AB/ABA/ABC

Features :

Compact structure, high cost performance, three-layer co-extruded, automatic roll change, high quality appearance and performance.

Characteristics of Product

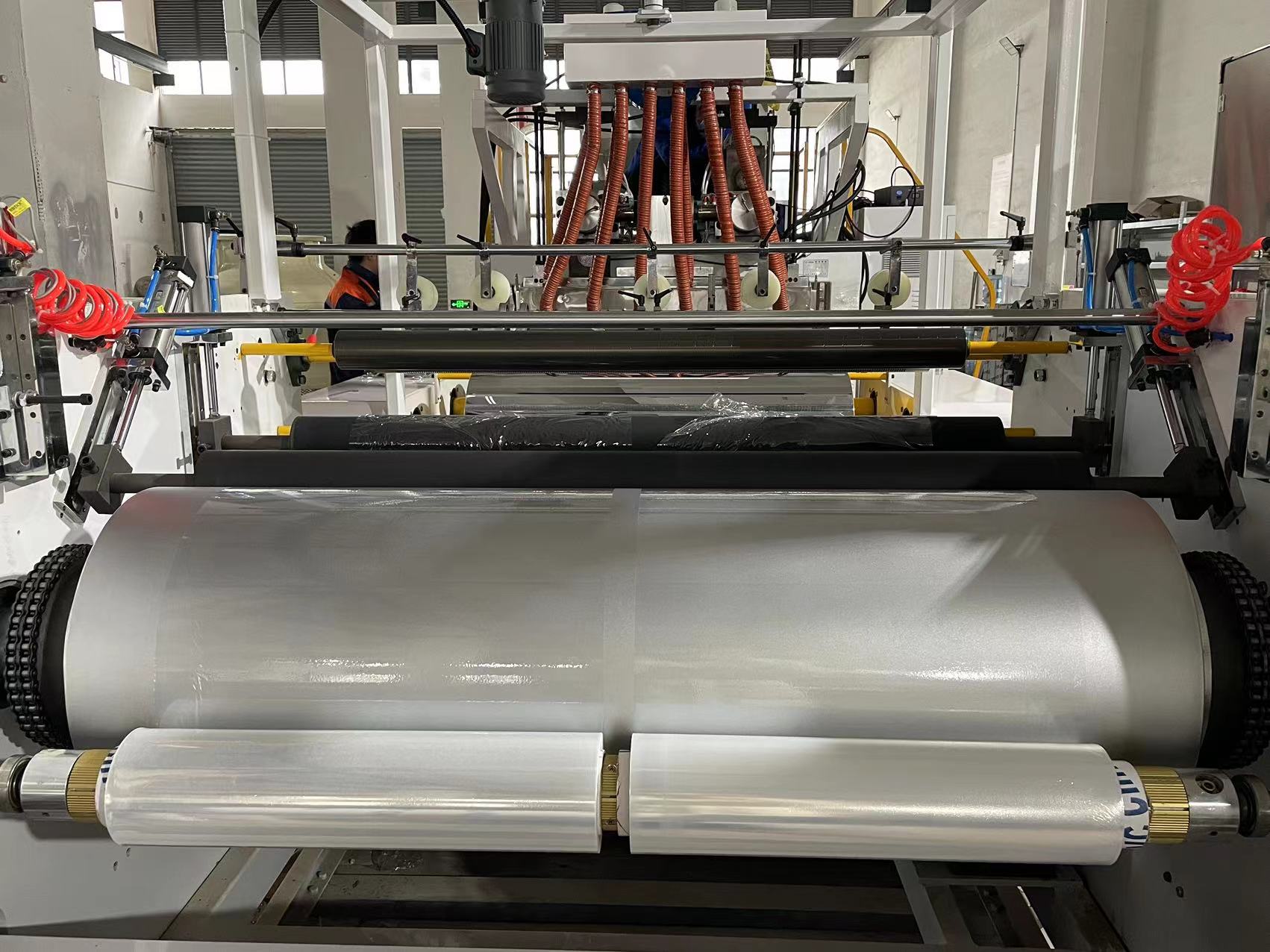

1. Adopt the latest winding system to cut the film instantly and change the rolls quickly, greatly reducing the waste at changing rolls and saving cost.

2. Adopt adjustable parting system with separate rollers, adjustable paring gap, with excellent effect.

3. The die for this line is optional with edge cover system to reduce the necking of film and ensure the stable production of film in high speed. This system can guarantee the stability of melt film edge, though the raw material and thickness of product are changed frequently. The background various requirements, like a smaller product order that need change the production technics and formula constantly. If without this system, the melt film edge will not be stableThis system always puts the same raw material (such as LLDPE) into edge of melt film and makes the edge melt at the same production environment all ;reason is that a modern production line must meet customers’

4. The whole line adopts PLC and touch screen with human-machine interface and supports long-distance detection by network which can offer all-round system maintenance, shorten the distance of space-time and realize commissioning in different places.

5. All the electric control parts are famous brands to ensure machine’s quality and reliable running.

Main Applications of Product

6. The cooling roller adopts major diameter and special flow to ensure good cooling and molding under high speed production.

|

Model |

KPS-55/75/55x1250mm (3 layer ) |

KPS-55/75x1250mm (2 layer) |

KPS-65/90x1850mm (2 layer) |

|

Screw diameter: |

55/75/55mm |

55/75 |

65/90 |

|

Production capacity: |

100-160kg/h |

60-150kg/h |

120-220kg/h |

|

Effective screw L/D: |

30:1 |

30:1 |

30:1 |

|

Thickness of film |

10µm-50µm |

10µm-50µm |

10µm-50µm |

|

Tolerance of thickness |

≤±5% |

≤±5% |

≤±5% |

|

Width of effective film |

1000mm(max) or 2*500mm |

1000mm(max) or 2*500mm |

1500mm(max) or 3*500mm |

|

Structure of film layers |

ABC |

AB or ABA |

AB or ABA |

|

Film material |

LLDPE or LLDPE+LDPE |

LLDPE or LLDPE+LDPE |

LLDPE orLLDPE+LDPE |

|

Electric powe |

≥90KW |

75KW |

110KW |

|

Machine dimension |

9000mm*3600mm*3500mm |

8000mm*3500mm*3200mm |

11000mm*3500mm*3800mm |

|

Machine weight |

8000kg |

7600kg |

12000kg |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|