Air Cooling Hot Cutting Plastic Film Recycling Machine

Descriptions:

The Air Cooling Hot Cutting Plastic Film Recycling Machine

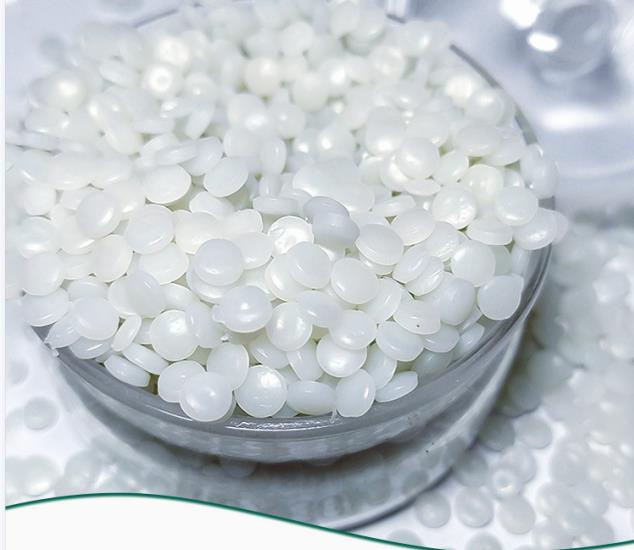

This raw materials like waste HDPE films is extruded through the extruder, and then are cooled through wind and cut hotly into granules, featuring in fine quality, bubble free and moisture free. The machine is equipped with a forced feeder, fast screen changer and automatic temperature-controller.

Feature:

1. Hot-cutting & wind cooling.

2. It is equipped with automatic constant temperature, motorized net changer (hydraulic net changer is optional).

3. It also can pelletize the crushing material after fitting with an force loader.

4. The cutting machine adopts speed regulating motor. Which can cut the material according to the feeding speed of the extruder, with such features as high output, low noise, stable performance and easy operation. It is a more ideal waste plastic film regenerative pelletizer.

5. Feeding unit adopts force feeder. (optional)

6. The helical gear reducer with hard teeth is applied to the extruder and the screw.

7. Screw and barrel are made of 38CrMoA1A with nitrogen treatment.

|

Model |

KP-B100 |

KP-B110 |

KP-B120 |

|

Diameter of Screw |

100mm |

110mm |

120mm |

|

L:D |

20:1 |

20:1 |

20:1 |

|

Speed of Screw |

10-110rpm |

10-110rpm |

10-110rpm |

|

Gearbox |

173 |

180 |

200 |

|

Motor Power |

22kw |

30kw |

37kw |

|

Output |

90kg/h |

120kg/h |

135kg/h |

|

Screen changer |

Hydraulic/ Motorized control |

||

|

Machine Weight |

2800kg |

3000kg |

3200kg |

|

Overail Dimensions |

4.2*1.5*1.8m |

4.4*1.5*1.8m |

4.6*1.5*2.3m |

|

|

|

|