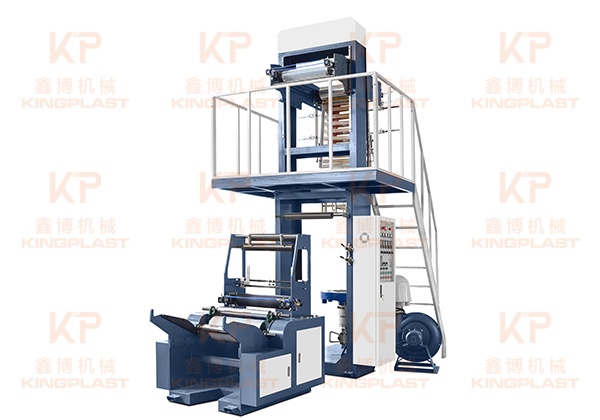

High Speed Mini Model Film blowing machine

Description:

Suitable material : HDPE , LDPE , LLDPE

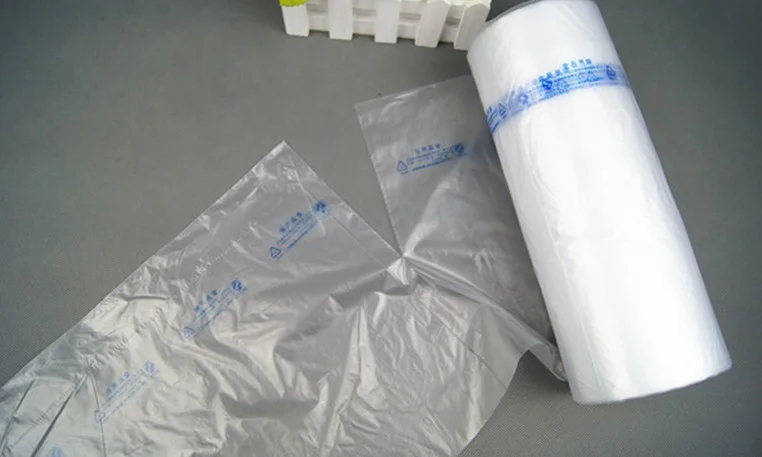

High Speed Film blowing machine is used to produce shirt bag/vest bag , garbage bag on roll ,flat bag , biodegradable bag , supermarket bag, shopping bag ,which are widely used for packing food,fruit,garments, textile,daily necessities and industrial products.

Feature:

High speed film blowing machine ,provides a good solution for general packaging and produces quality film of LDPE,HDPE,LLDPE. Film width can be customized according to customer requirements from 200mm to 600mm.High precision die head, high efficiency screw and barrel, and cooling air ring provide good film thickness control and resistance.

The screw is made of bimetallic , and barrel is made of 38 CrMoAl, and been nitrided.

The winding unit adopt torgue motor to keep proper tension and make the film much smooth and change rolling easy

Optional Equipment:

1. Auto-loader

2. Dryer

3. Corona treater

4. Air compressor

5. High-speed screen changer

6. Air shaft

|

Model |

KP-HM45 |

KP-HM50 |

|

Suitable Material |

HDPE LDPE LLDPE |

HDPE LDPE LLDPE |

|

Film Width(mm) |

200-500 |

200-600 |

|

Film Thickness(mm) |

0.009-0.05 |

0.009-0.05 |

|

Max Extrusion Capacity(kg/hr) |

HDPE: 50 |

HDPE: 60 |

|

Screw Diameter(mm) |

Φ45 |

Φ50 |

|

Main Motor(kw) |

15 |

18.5 |

|

Screw L/D Length |

32:1 |

32:1 |

|

Screw Material |

Bimetallic |

Bimetallic |

|

Cylinder Material |

SACM-645/38 CRMOALA |

SACM-645/38 CRMOALA |

|

Double Lip Air Ring |

1 |

1 |

|

Center steady stick |

1 |

1 |

|

Die Size(mm) |

60 |

80 |

|

Air Blower(kw) |

4 |

5.5 |

|

Take Up Motor (kw) |

1.5 |

1.5 |

|

Winding motor (N.m) |

10 |

10 |

|

Cover dimension(m) |

3.8*1.6*3.6 |

4.2*1.8*3.6 |

|

|

|

|

|

|

|

|

|

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)