Twin Die Head Film Blowing Machine

Descriptions:

Suitable material : HDPE, LDPE ,LLDPE

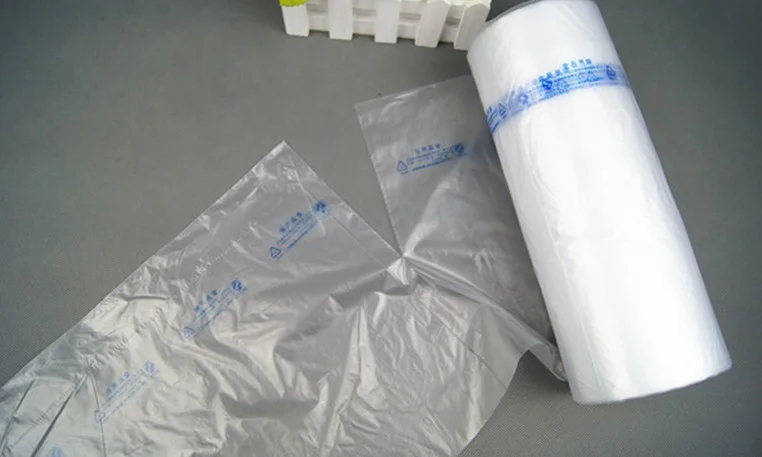

Twin die head film blowing machine is used to is widely used in various industries for producing different types of plastic bags. such as t shirt bag/vest bag , garbage bag on roll ,flat bag , supermarket bag, shopping bag.

Feature:

Twin Die Head film blowing machine ,provides a good solution for general packaging and produces quality film of LDPE,HDPE,LLDPE. Film width can be customized according to customer requirements, from 200mm to 1000mm. High precision die head and cooling air ring provide good film thickness control and resistance.

twin die head film blowing machine has two separate die heads, allowing for the simultaneous production of two film rolls. Each die head is connected to a separate extruder, which melts the plastic resin and feeds it into the die. The molten plastic is then pushed through the die, where it is shaped into a thin film.

Twin die die film blowing machine simplifies the production process by eliminating the need for die changes when switching between different film types. This reduces downtime and increases overall production efficiency.

The twin die head design increases the production output of the machine as it allows for the simultaneous production of two film rolls. This can be especially beneficial for manufacturers looking to increase their production capacity or produce different types of films simultaneously.

Optional Equipment:

1. Auto Loader

2. CoronaTreater

3. Rotary die head

4. FastScreen Changer

5. Auto Winder

6. Air shaft

|

Model |

KP-SD55-500 |

KP-SD60-600 |

KP-SD70-800 |

|

Suitable material |

LDPE, LLDPE, HDPE, |

||

|

Film width(mm) |

200-500 |

300-600 |

400-800 |

|

Film thickness(mm) |

0.03-0.15 |

||

|

Max output(kg/hr) |

40 |

55 |

70 |

|

Extruder |

|||

|

Screw diameter(mm) |

Φ55 |

Φ60 |

Φ70 |

|

Screw L/D Ratio |

30:1 |

30:1 |

30:1 |

|

Screw material |

Bimetallic |

||

|

Cylinder material |

38 CRMOALA |

||

|

Cylinder cooling |

370w*2 |

370w*2 |

370w*3 |

|

Driving motor (kW) |

22 |

30 |

37 |

|

Temperature control |

3 |

3 |

4 |

|

Die head |

|||

|

Die size(mm) |

60 |

80 |

100 |

|

Temperature control |

1 |

1 |

1 |

|

Air ring |

2 |

2 |

2 |

|

Air blower (kw) |

2.2kw*2 |

3kw*2 |

4kw*2 |

|

Take up unit |

|||

|

Roller width (mm) |

500*2 |

700*2 |

900*2 |

|

Effective width (mm) |

400*2 |

600*2 |

800*2 |

|

Take up speed (m/min) |

10-100 |

10-100 |

10-100 |

|

Take up motor (kw) |

0.75 |

1.5 |

1.5 |

|

Winding unit |

|||

|

Winding motor (N.m) |

10 |

10 |

10 |

|

Winding speed(m/min) |

10-100 |

10-100 |

10-100 |

|

Overall dimension(m) |

4.5*2.2*3.9 |

5*2.4*4.2 |

5.5*2.6*4.5 |

|

|

|

|

|

|

|

|

|

|

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)