Rotary Die & Double Rewinder LDPE Film Blowing Machine for Shrinkable/ Agriculture/ Mulch Film

Descriptions:

Suitable material : HDPE , LDPE , LLDPE

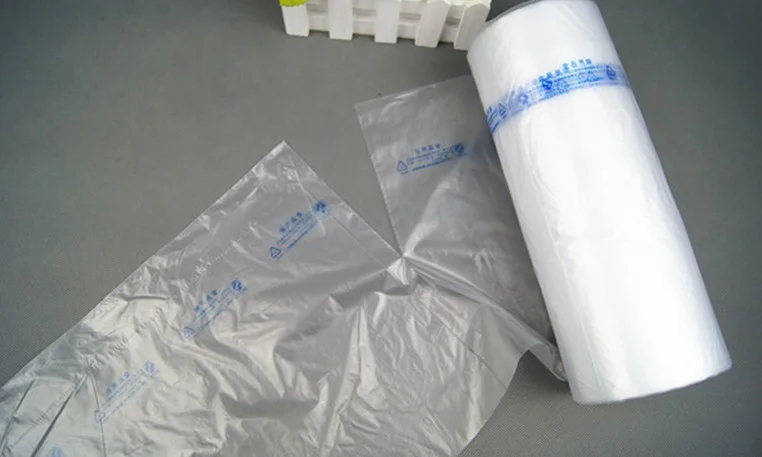

Thesingle layer rotary die agriculture film blowing machine is used to vest bag , agriculture film ,genmembrane film, garbage bag ,flat bag , biodegradable bag

Feature:

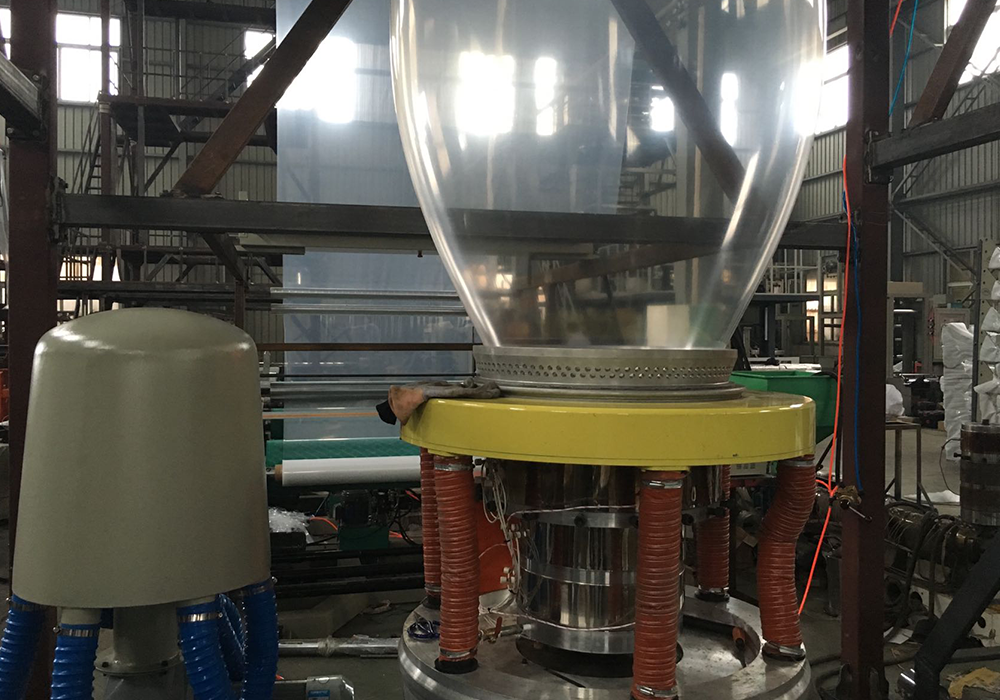

1. Single layer rotary die agriculture film blowing machine , it produce agriculture film , genmembrane film,ground,shack and package film of LDPE,HDPE,LLDPE. Film width can be customized according to customer requirements, from 800mm to 2000mm. High precision die head and cooling air ring provide good film thickness control and resistance.

2. LDPE film is a type of agricultural film made from low-density polyethylene, which is used to cover the surface of farmland to provide insulation, moisture retention, rain protection, and weed suppression. The large blown film machine for agricultural film and shrink film production is the equipment used to manufacture LDPE film.

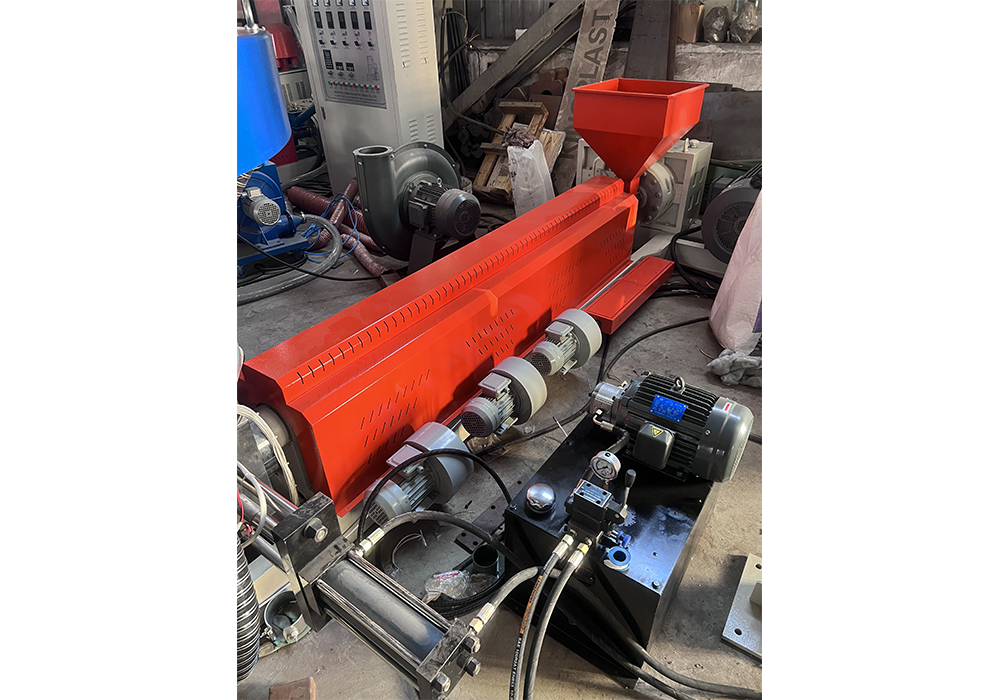

3. This large blown film machine typically consists of an extruder, a die head, a feeding device, a cooling system, a stretching device, and a winding device. Firstly, LDPE pellets are heated and melted in the extruder, then extruded through the die head into a thin film. The film is then cooled by the cooling system to solidify it. Next, the stretching device stretches the film to give it certain strength and elongation. Finally, the film is wound up into finished rolls by the winding device.

4. The large blown film machine can produce high-quality LDPE film with features such as high production efficiency, high automation, and easy operation. It is widely used in agricultural production, increasing soil utilization and crop yield, while effectively resisting the impact of natural disasters.

Optional Equipment:

1. Auto Loader

2. Corona treater

3. Mechanics Screen Changer

4. Auto Winder

|

Model |

KP-B75 |

KP-B120 |

|

Suitable material |

HDPE LDPE LLDPE |

|

|

Film width(mm) |

600-1500 |

1200-2000 |

|

Film thickness(mm) |

LD: 0.02-0.2 |

LD: 0.02-0.2 |

|

Max.Extrusion output(kg/hr) |

LD: 100-120 |

LD :120-150 |

|

Extruder |

||

|

Screw diameter(mm) |

Φ75 |

Ф120 |

|

Screw L/D length |

30:1/32:1 |

|

|

Screw material |

Bimetallic |

|

|

Cylinder material |

SACM-645/38CRMOALA |

|

|

Cylinder cooling |

550wx3 |

550wx4 |

|

Driving motor (kw) |

30-37 |

45-55 |

|

Temperature control |

4 |

5 |

|

Type of die |

||

|

Die size(mm) |

Ф350 |

Ф500 |

|

Temperature control |

3 |

4 |

|

Air ring |

1 pcs , dual lip air ring |

|

|

Air blower(kw) |

7.5 |

11 |

|

Center steady stick |

/ |

|

|

Take-up unit |

||

|

Roller width(mm) |

ф165×1600 |

ф165×2100 |

|

Height adjustable type |

/ |

|

|

Take-up speed(m/min) |

10-80 |

10-80 |

|

Take-up motor(kw) |

2.2 |

3 |

|

Winding unit |

||

|

Type |

Surface friction type |

|

|

Winding motor(N.m) |

10 |

10 |

|

Winding speed(m/min) |

10-60 |

10-60 |

|

Outline dimension (LXWXH) |

6X3X7.5M |

7.1X3.5X9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)