Normal Type Mono Layer Film Blowing Machine

Decriptions :

Suitable material : HDPE ,LDPE ,LLDPE

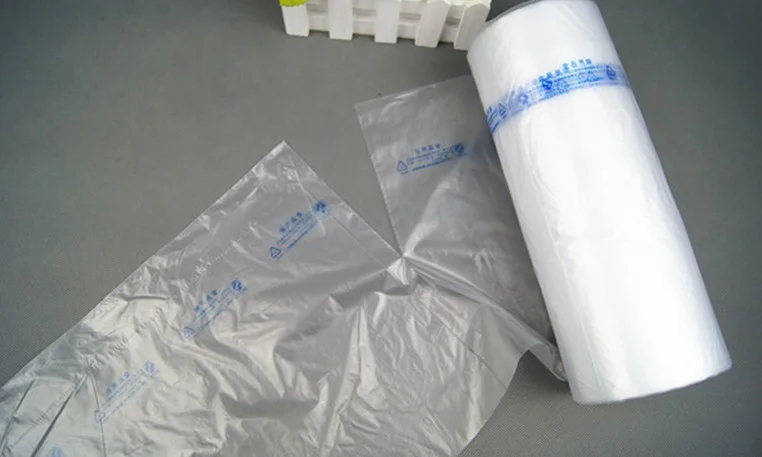

The normal type film blowing machine is used to produce t shirt bag/vest bag , garbage bag on roll ,flat bag , supermarket bag, shopping bag, biodegradable bag , which are widely used for packing food,fruit,garments, textile,daily necessities and industrial products.

Feature:

Standard type film blowing machine ,provides a good solution for general packaging and produces quality film of LDPE,HDPE,LLDPE. Such as t shirt bag/vest bag , bag on roll garbage bag ,flat bag , degradable bag , supermarket bag, shopping bag. Film width can be customized according to customer requirements, from 200mm to 1200mm. High precision die head and cooling air ring provide good film thickness control and resistance.

The working principle of a single-screw blown film machine is as follows:

1. Plastic pellet feeding: Plastic pellets are fed into the machine through the feeding hopper.

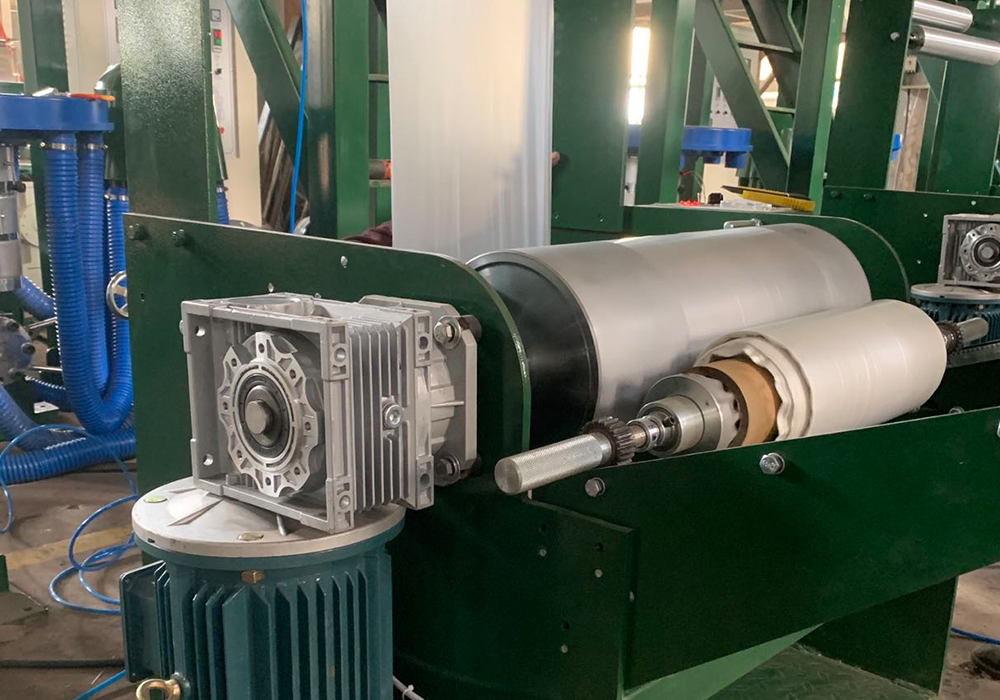

2. Plastic melting: Near the feeding hopper, the plastic pellets are pushed forward by the rotating screw. The screw is made of bimetallic , and barrel is made of 38 CrMoAl, and been nitrided. During this process, the plastic pellets are subjected to shear and friction forces, gradually melting into a liquid state.

3. Plastic extrusion: Once the plastic is fully melted, it is pushed to the back end of the screw and extruded through a die head. The die head is a metal plate with a specific shape that allows the molten plastic to be extruded evenly and at the desired thickness, forming a continuous film.

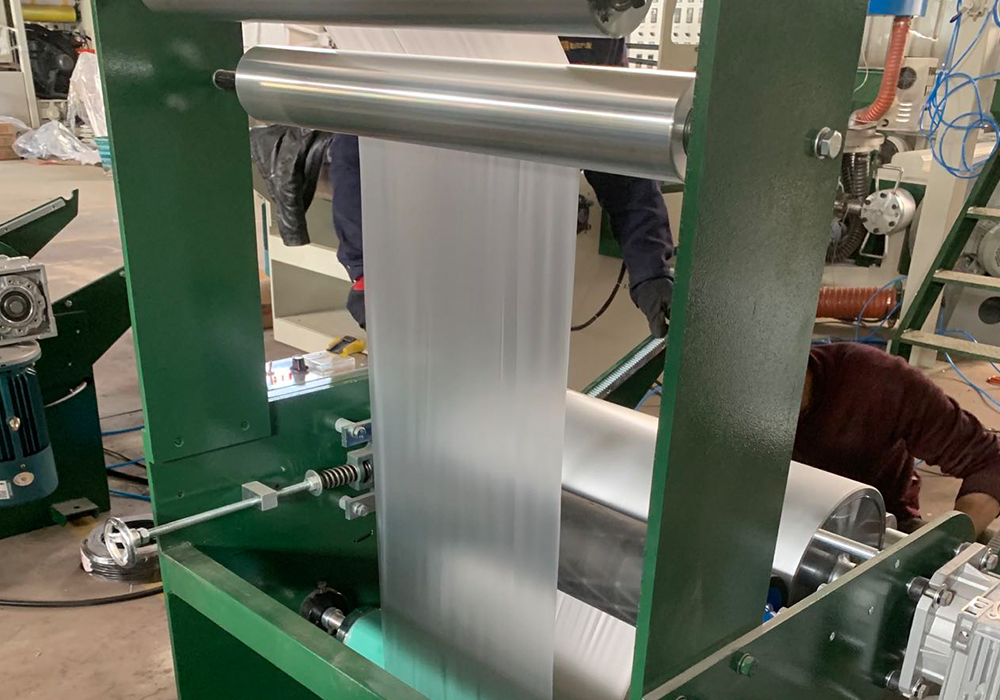

4. Cooling and solidification: The extruded plastic film is rapidly cooled, either by cooling rolls or a water bath, to quickly solidify it and obtain a flat plastic film.

5. Winding: The cooled and solidified plastic film is wound onto a roll using a winding device, creating a large or small roll of plastic film products.

Optional Equipment:

1. Auto-loader

2. Corona treater

3. Rotary die head

4. Double winder

5. High speed screen changer

|

(KP-N Series) |

(Second Take Up Unit) |

(KP-B Series Double Winder +Rotary Die) |

|

|

|

|

Model |

KP-N45 |

KP-N50 |

KP-N55 |

KP-N60 |

KP- N65 |

|

|

Suitable material |

HDPE LDPE LLDPE |

|||||

|

Film width(mm) |

100-500 |

300-600 |

400-800 |

500-1000 |

600-1200 |

|

|

Film thickness(mm) |

HD |

0.009-0.05 |

0.009-0.15 |

|||

|

LD |

0.02-0.15 |

0.03-0.15 |

||||

|

Max.Extrusion output(kg/hr) |

HD |

35 |

40 |

50 |

55 |

65 |

|

LD |

40 |

42 |

60 |

70 |

80 |

|

|

Extruder |

||||||

|

Screw diameter(mm) |

φ45 |

φ50 |

φ55 |

φ60 |

φ65 |

|

|

Screw L/D length |

30:1/32:1 |

|||||

|

Screw material |

Bimetallic |

|||||

|

Cylinder material |

SACM-645/38CRMOALA |

|||||

|

Cylinder cooling |

250wx2 |

250wx2 |

370wx2 |

370wx3 |

550wx2 |

|

|

Driving motor(kw) |

11 |

15 |

18.5 |

22 |

30 |

|

|

Temperature control |

3 |

3 |

3 |

3 |

4 |

|

|

Type of die |

||||||

|

Die size(mm) |

HD |

ф60/80 |

ф80/100 |

ф100/120 |

ф100/120 |

ф100/150 |

|

LD |

ф100/120 |

ф120/150 |

ф180/200 |

Ф200/220 |

ф220/ 250 |

|

|

Temperature control |

3 |

|||||

|

Air ring |

1 pcs |

|||||

|

Air blower(kw) |

22 |

3 |

3 |

4 |

5.5 |

|

|

Center steady stick |

1 |

|||||

|

Take-up unit |

||||||

|

Roller width(mm) |

ф165×600 |

ф165×700 |

ф165×900 |

ф165×1100 |

ф165×1300 |

|

|

Height adjustable type |

/ |

|||||

|

Take-up speed(m/min) |

10-100 |

10-100 |

10-80 |

10-80 |

10-80 |

|

|

Take-up motor(kw) |

0.75 |

1.5 |

1.5 |

1.5 |

2.2 |

|

|

Winding unit |

||||||

|

Type |

Surface friction type |

|||||

|

Winding motor(N.m) |

10 |

10 |

10 |

16 |

16 |

|

|

Winding speed(m/min) |

10-100 |

10-100 |

10-80 |

10-80 |

10-80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)